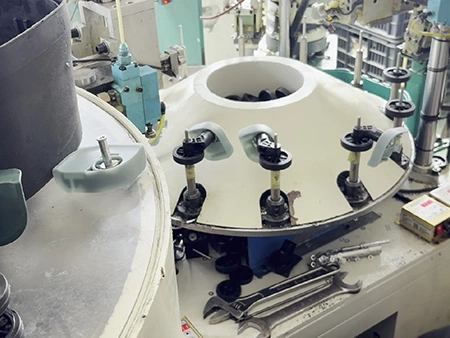

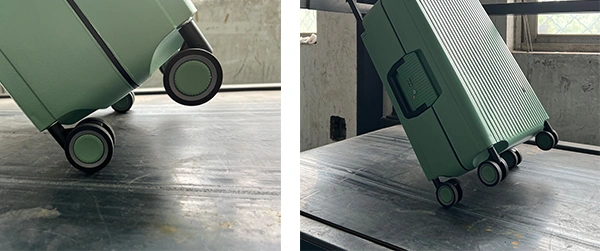

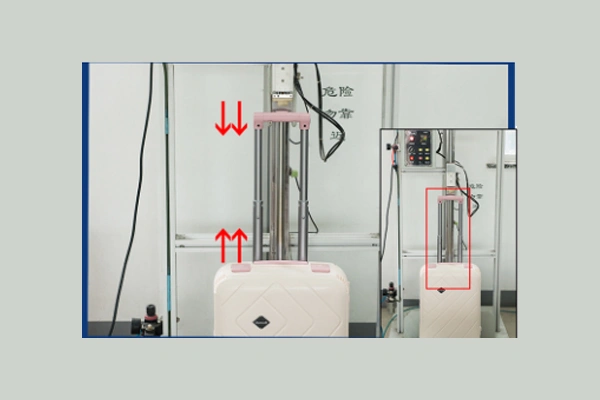

BUBULE’s factory spans 45,000 m² and brings 28 years of experience in the research and production of PP luggage. The facility is divided into specialized zones, including injection molding, accessory assembly, lining production, and quality inspection. With 8 main workshops, 88 injection molding machines, 60 sewing machines, and 15 automated production lines, the factory integrates robotic arms and conveyor systems to create a modern, semi-automated facility capable of producing over 10,000 luggage pieces daily. Continuous R&D and technological upgrades ensure material independence and innovation, while stringent quality control in a clean, standardized environment includes over 30 inspection steps, compliant with ISO9001 and ISO14001 standards.